诺辉承接三棵树美缝剂自动化生产线

摘要:2021年11月,经过多轮角逐

NOVA undertakes the automatic sewing agent production line of 3 TREES

2021年11月,经过多轮角逐,综合专业行业技术(侧重)与商务条款间的对比,上海诺辉成功中标三棵树涂料股份有限公司(安徽工厂)美缝剂全自动生产线EPC项目,值得特别说明的是,在此之前,三棵树全国多个涂料生产基地,从未运用EPC总承包的模式新增产线设备建设,本次选择诺辉作为该模式在三棵树实际产线建设项目中首次运用,是基于诺辉特有的EPC项目管理经验,以及实地考察由诺辉承接的多个EPC总承包实例后的一次尝试,同时也是对诺辉作为国内专业的精细化工设备制造、系统集成成熟经验的肯定;

In November 2021, NOVA successfully got the bid for the EPC project of 3 TREES Coatingsafter several rounds of competition between professional industry business and technology terms which is more important. In particular, before this, many paint production bases of 3trees across the country have never used the EPC general contracting model to build new production line equipment. This time, NOVA is selected as the model for the actual production line construction project of 3trees, which is based on NOVA's unique EPC project management experience, as well as on-site investigation of several EPC general contracting examples undertaken by NOVA. At the same time, it is also an affirmation of NOVA's mature experience as a professional fine chemical equipment manufacturer and system integration in China.

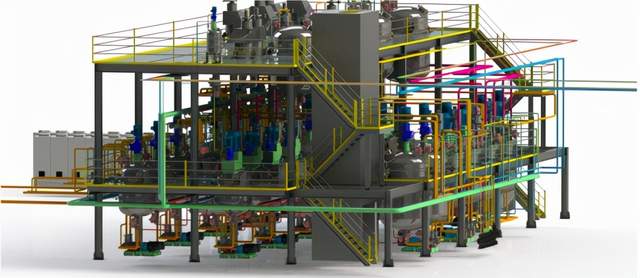

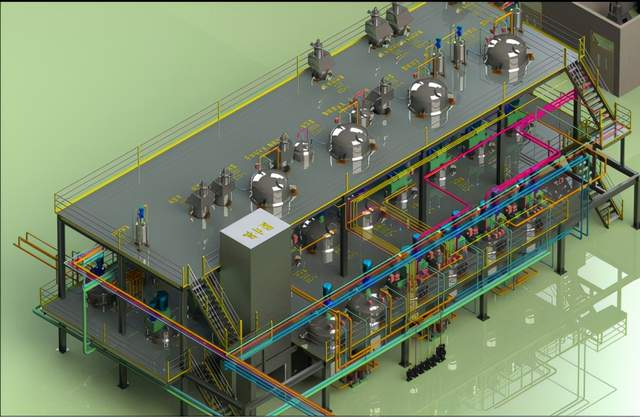

该生产线包括工艺设计、设备制作、钢结构搭建、现场安装、管道仪表系统、自动化控制系统等全部工作;该生产线建成后,将是目前国内规模最大、自动化程度最高的美缝剂生产线,整条产线由2条A组分生产线,12条B组分生产线组成。

The production line includes process design, equipment manufacture, steel structure construction, on-site installation, pipeline instrumentation system, and automatic control system, etc. After the production line is completed, it will be the largest and most automated groutagent production line in China. The line consists of 2 A component production lines and 12 B component production lines.

系统包含:

全自动粉体配料系统

全自动液体配料系统

全自动混合搅拌设备

全自动调色混合搅拌设备

全自动化控制系统

The system includes: Fully automatic powder batching system, fully automatic liquid batching system and automatic mixing equipment, fully automatic color mixingequipment, as well as fully automatic control system

(产线三维模型图)

(3D model drawing of production line)

系统特点:System characteristics

1、粉体投料系统无尘化、自动化,自带过滤滤芯及除尘系统,粉体补料过程中无粉尘飞扬;粉体根据配方需求全自动配料;极大的降低人工成本和改善工作环境;

The powder feeding system is dust-free and automatic, with its own filter element and dust removal system, and there is no dust flying in the process of powder feeding. The powder is fed automatically according to the formula and greatly reducing labor costs and improving the working environment.

2、根据高粘度的物料特性,特殊设计混合搅拌结构,超高效混合,生产罐及调色罐真空设计压力为100pa;

According to the characteristics of high viscosity materials, the mixing structure is specially designed for ultra efficient mixing. The vacuum design pressure of production tank and color mixing tank is 100Pa.

3、B组分生产罐采用专色专罐,免清洗,无液废、固废;

The production tank of component B uses different tanks for each color, which is free of cleaning and liquid & solid waste.

4、高效智能,自动化程度高,具备一键启动条件;液体配料及物料转移根据配方需求全自动运行;

High efficiency, high degree of automation, with one-key start condition.Liquid batching and material conveying are fully automatic operated according to formula.

5、成品采用恒压系统泵送至灌装机,这个输送过程全部在密闭的管道中进行,与全自动灌装机联动。

The finished product is pumped to the filling machine by a constant pressure system. This conveying process is all carried out in a closed pipeline, which is linked with the automatic filling machine.

目前项目正在安装进行中

At present, the project is under installation

(钢结构平台搭建进度照片)

(Photo of steel structure platform construction progress)

(设备安装就位进度照片)

(Photo of equipment on-site and installation)

标签:

热门资讯排行

- 资讯专区

- 图片专区

- 品牌专区